22 Jun Downhole Gyros Explained

By Mike Ayris (Senior Technical Advisor, Downhole surveys) and Rune Lindhjem (Product Manager, Devico)

A Brief History of Downhole Gyros

“I have been involved in the downhole surveying industry for over 30 years and have seen a lot of survey instruments come and go over that time. I started my business in 1989, with a film based multishot camera capable of recording up to 2 hours of readings taken every 2 minutes. Those were the days, where all you could do was hope that the film had developed. I’m sure some readers will remember the failed film single shot discs littering the collar and the frustration that went with it.”

Mike Ayris – Senior Technical Advisor, Downhole Surveys

Today the technology is very different with digital instruments recording and saving survey data almost instantly and at any interval. Some modern gyros may even take 10 readings a second, an astonishing 1200 times more data. The advancement in microchip technology and onboard processing power, with low power consumption, has further led to a miniaturisation of gyro instruments. One of the smallest downhole gyros on the market measures just 140mm long with a 25mm outer diameter (including the 3V battery).

Where the gyro instruments previously required a delicate spinning mass sensor, prone to calibration issues, todays instruments are made with highly robust solid state sensors, making them ideal for the drilling industry.

Types of Downhole Gyros: Explained

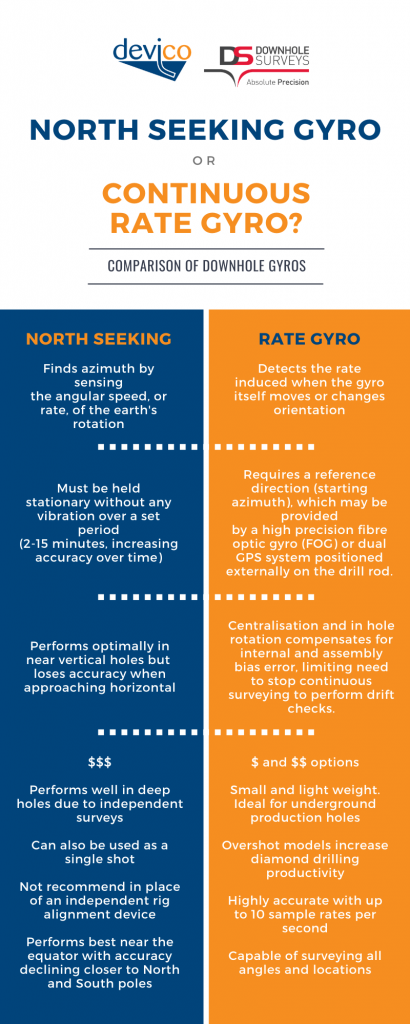

Downhole gyros can be divided into two main categories: the ‘north seeking’ gyros and the ‘rate’, or reference, gyros; each with their own benefits and limitations.

The north seeking gyros find azimuth by sensing the angular speed, or rate, of the earth’s rotation. Along with the gravitational field, it uses this to calculate the orientation of the instrument with reference to the earth’s axis of rotation. In order to properly estimate the north direction, the north seeking gyros must be held stationary without any induced vibration over a set period. The time it takes to seek north may be anything from 2 minutes to 15 minutes, increasing in accuracy over time.

Rate gyros primarily detect the rate induced when the gyro itself moves or changes orientation. For that reason, they will sense the deviation or change from the straight line that occurs as the gyro moves down the hole. In order to display the correct trajectory of the hole a reference direction must be added to the azimuth data. Usually the reference direction is the starting azimuth, which may be provided by a high precision fibre optic gyro (FOG) or dual GPS system positioned externally on the drill rod.

Continuous Gyros

So, what is a continuous gyro? In today’s mining industry there is a selection of both north seeking and rate gyros being marketed as continuous, i.e. they can measure the hole from top to bottom without having to stop at regular intervals. This is done by utilising the principle of rate gyros where the high sample rate capability makes it possible to continuously track the small changes in trajectory. It is worth noting that north seeking gyros do not seek north in continuous mode, but instead measure the rate of change in a similar way as a rate gyro.

Bias Compensation

When surveying continuously it is particularly important to compensate for internal and assembly bias error. These types of error can be associated with sensor accuracy, build alignment and barrel straightness, and can cause azimuth offsets and error build ups in the survey data. Some compensation is typically done by stopping at regular intervals to perform drift checks or seek north. However, this is time consuming and does not compensate for external factors like barrel straightness and centralization issues. An optional or complementary way to compensate for the bias error is to rotate the survey instrument at a constant rate during the surveying process. Downhole Surveys have developed a patent pending centraliser system designed to centralise and rotate the survey instrument approximately 90 degrees each 3m travelled, resulting in a zeroing of bias error each 12m travelled.

While this type of rotation is especially suitable for continuous surveys, where the time between stops is long, it is also beneficial in multishot surveys to correct for internal bias and increase surveying accuracy.

Limitations of Gyro Instruments

Whereas the limitation of a rate gyro is obvious, as it does not measure true direction, it is important to understand that north seeking gyros also have several limitations, not found in rate gyros.

Many of the north seeking gyros will only perform optimally in near vertical holes and quickly loose accuracy when approaching horizontal. This is an effect of the sensor package used in the specific tools being limited in certain directions.

The accuracy of a north seeking gyro will always be best near the equator and decline the closer it gets to the north or south poles. The reason being that the earth’s gravity direction and axis of rotation becomes parallel at the poles, making it more and more difficult, and in the end impossible, to estimate the north direction.

The direction the north seeking gyro is pointing has a certain effect on the accuracy of the north estimate as well. The most accurate data will be achieved in near north-south direction, or parallel with the earth’s rotation axis, while becoming more affected by sensor inaccuracies when pointing east-west. The effect of this is generally higher when the hole is either far from vertical or at a higher latitude.

Downhole north seeking gyros are also generally not recommended to be used in place of an independent rig alignment device, as they are not considered to be as accurate as the fibre-optic gyros these devices use.

Selecting the Right Downhole Gyro

No one gyro will be suitable for all applications. For example:

- If the application is to survey 32m production upholes, then weight and ease of handling would be a major consideration.

- Similarly, for underground a rate gyro system may be preferable due to smaller size, along with the limitations in north seeking gyros close to horizontal.

- If drilling productivity is critical, then a continuous gyro capable of surveying at a minimum speed of 70m/min would be ideal. For coring operations an overshot model will also help save time.

- If price is a concern, north seeking gyros are generally more expensive than rate gyros.

- If directional drilling, then sample interval needs to be considered. We recommend no greater than 3m spacing between survey readings to ensure dog legs are captured.

- For vertical large diameter geotechnical drilling, availability of proper centralisation means is crucial.

- If surveys will be performed by several operators ease of operation and software is important. Survey data should always be processed through a series of quality assurance (QA) checks, to ensure the accuracy of data being handed over. A cloud based data management system is also ideal for simplifying the data transfer process and minimising any input/output data errors. These systems are now becoming more commonplace in the downhole surveying industry.

The Future of Downhole Surveying

Gyros are getting smaller, using less battery power and becoming more robust, allowing them to potentially ‘Measure While Drill’ or MWD. The race is on to develop a true MWD system within the mineral industry.

We are closer than ever to MWD with the overshot survey methods introduced in recent years. The challenge will be to fit a gyro within the innertube or an extension of, and record drill hole deviation whilst drilling the hole.

As underground mines embrace high speed Wi-Fi, we will see the development of real time communication between geologists and drillers greatly improve. Geologists could potentially track several holes as they progress, alerting the underground drillers if any corrective action is required, from their desk located anywhere in the world.

Future technologies and innovations are rapidly improving drilling productivity and safety, and the best is yet to come.

Sorry, the comment form is closed at this time.