DeviGyro FAQ Page

DeviGyro Specifications

Is the DeviGyro north seeking?

The DeviGyro is not a north seeking Gyro in the true sense of the word. It is a high precision continuous rate gyro using north seeking principles and proprietary algorithms to determine the drill hole path from a known direction.

Most continuous north seeking gyros operate in the same way. They determine a start direction and then measure the “rate“ of change from the initial reference.

Downhole Surveys recommends combining the DeviGyro with the DeviAligner in order to get a powerful north seeking system that is superior to existing north seeking borehole tools. Visit the DeviAligner product page or enquire about our reduced package pricing today.

Read our article Downhole Gyros Explained, to learn more about the types of gyros available and their suited applications.

What is the size of the DeviGyro sensor?

25mm x 110mm. It can fit in your pocket it’s that small!

Does the DeviGyro have any limitations with respect to borehole angles or latitude?

The DeviGyro can survey all angles and there are now three different running gear configurations to suit your drilling application.

DeviGyro RG40 (standard): RC, diamond, geotechnical drilling and pilot holes

DeviGyro Overshot Xpress (OX): Diamond drilling. Survey whilst pulling core tube.

DeviGyro RG30: blast hole surveying

How long does the DeviGyro battery last?

The DeviGyro runs on a 3V replaceable Panasonic CR123A battery. The normal operating life is around 25 hours continuous use. A low battery warning appears on the DeviGyro App at 2.7V.

DeviGyro Operation

What is the DeviGyro's maximum operating speed?

The DeviGyro has been succesfully tested at speeds of 180m/min! However Downhole Surveys recommends the DeviGyro be operated at a safe running speed of 60 – 80m/min and not over 100m/min.

Do I need to stop the continuous survey at any time?

A zero velocity update is required every 10 minutes for a period of 15 seconds. The DeviGyro App prompts the user for these stops.

Does the DeviGyro require a warm-up period?

There is no gyro warm up time required. However, best practice is to allow the DeviGyro time to temperature stabilise to the environment it is working in.

Can I tie on a Survey?

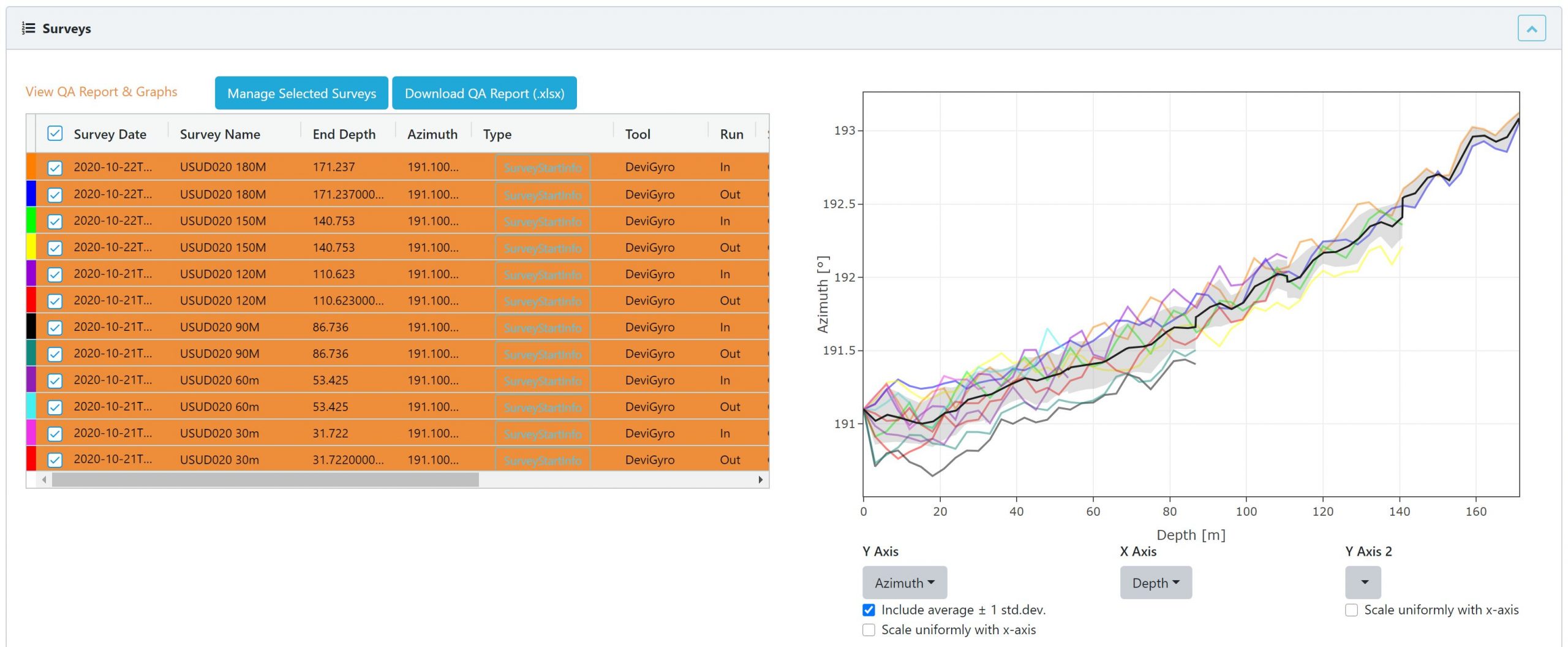

Yes a tie on survey can be conducted, however best practice is to conduct a new survey each time from the collar and apply weighted averaging in the DeviCloud survey data management system to improve survey precision.

DeviGyro Equipment

How long is the DeviGyro when assembled?

What is a DeviCounter and do I need to use one?

A critical component supplied with the continuous DeviGyro is the optical depth encoder, the DeviCounter. The Devicounter is attached to the drill rig wireline, recording time and depth, whilst the DeviGyro records time and navigation data. After surveying is completed the two sets of data are merged.

Unlike some counter systems the DeviCounter stores the depth data internally, correcting errors prior to merging.

The DeviGyro can also be run in manual mode where a depth interval is manually entered, for example when using a fibre glass rodder or polypipe.

Can the DeviGyro OX be retrieved in the case of a stuck tube?

The shear pin used in the OX assembly is designed to break under a specific amount of pressure (approx. shear strength 17,5 kN), preventing the risk of having to cut the wireline and leave the tool down the hole if the tube is stuck. Only the latch unit of the OX will remain in the hole when this pin breaks and the survey can still be completed.

Survey Results and Accuracy

How accurate is the DeviGyro?

- Inclination accuracy: ±0.1°

- Direction accuracy: ±0.5°

- Tool face accuracy: ±0.2°

What quality checks are there for the DeviGyro?

- Misclose: For a DeviGyro survey to pass there must be less than 0.5% standard deviation of 5m/1000m

- A valid standstill period must be recorded at the start and end of every survey

- Low battery warning